Are you wondering whether it’s time to use the potential of Enterprise Resource Planning (ERP) software to take your small manufacturing business to the next level? Or have you already known that you need an ERP solution but aren’t sure which software will meet your budget while still scaling with your business? Let’s check through this list of the top ERP systems for small manufacturing businesses for 2024.

What Is an ERP System in Manufacturing?

ERP in manufacturing is a comprehensive solution that meets all the professional needs of manufacturing companies. It combines multiple company processes into a single system, including production planning, inventory management, supply chain management, finance, human resources, and customer relationship management.

ERP software enables manufacturers to make more informed decisions, streamline processes, and increase overall efficiency by delivering real-time visibility and data-driven insights.

Roles of An ERP System in Manufacturing

#1 Real-time Insights and Decision-Making

One of the main benefits of deploying an ERP system in a manufacturing organization is access to real-time data. Managers can make informed decisions more quickly with access to accurate and up-to-date information. By examining data on production cycles, inventory levels, customer demand, and financial performance, manufacturers may detect bottlenecks, optimize resource allocation, and match their strategy with market trends.

#2 Increase Efficiency and Data Integration

ERP systems aim to combine numerous areas of a manufacturing company’s operations onto a single platform. ERP software improves supply chain management, production planning, inventory control, and quality assurance, providing seamless departmental cooperation. Manufacturers may dramatically improve productivity, lower costs, and eliminate data silos by automating workflows and eliminating manual processes.

#3 Scalability and Flexibility

As a company grows, its operational requirements change. ERP systems provide scalability and flexibility to meet changing business needs. A strong ERP solution can handle the complexity of expanding into new markets, broadening product lines, and managing various sites. Manufacturers may scale their operations smoothly by giving a single picture of the entire business while retaining process consistency and control.

5 Best ERP Systems For Small Manufacturing Businesses

#1 Microsoft Dynamics 365 Business Central

Microsoft Dynamics 365 Business Central is a configurable ERP system that helps manufacturers streamline their operations. It has advanced features such as demand forecasting, production planning, quality control, and warehouse management.

Manufacturers may enhance productivity by leveraging familiar interfaces and integrating seamlessly with other Microsoft applications such as Excel, Outlook, and Power BI. The cloud-based architecture of Business Central provides scalability and accessibility from any device.

However, SMEs may have issues with scalability and pricing. While Dynamics 365 Business Central is designed to adapt to business growth, SMEs experiencing rapid expansion may eventually outgrow the system’s capabilities, causing a move to a more powerful ERP solution.

Regarding cost, Dynamics 365 Business Central’s licensing, implementation, and annual subscription fees can be too costly for some SMEs. The whole cost of ownership, including training, maintenance, and adaptations, should be carefully considered.

#2 SAP S/4HANA

SAP S/4HANA is a complete ERP solution built primarily for the manufacturing industry. It comprehensively integrates procurement, production, sales, and service processes. Manufacturers may use its powerful analytics capabilities and real-time data processing to make data-driven decisions that increase efficiency and customer satisfaction.

SAP S/4HANA also supports smart technologies like artificial intelligence (AI) and machine learning (ML), which facilitate predictive analytics and automation. SAP can be excellent software, but it might be too expensive for SMEs due to its excessive cost per person.

Read more: Top 10 Best ERP Solutions for Small Businesses

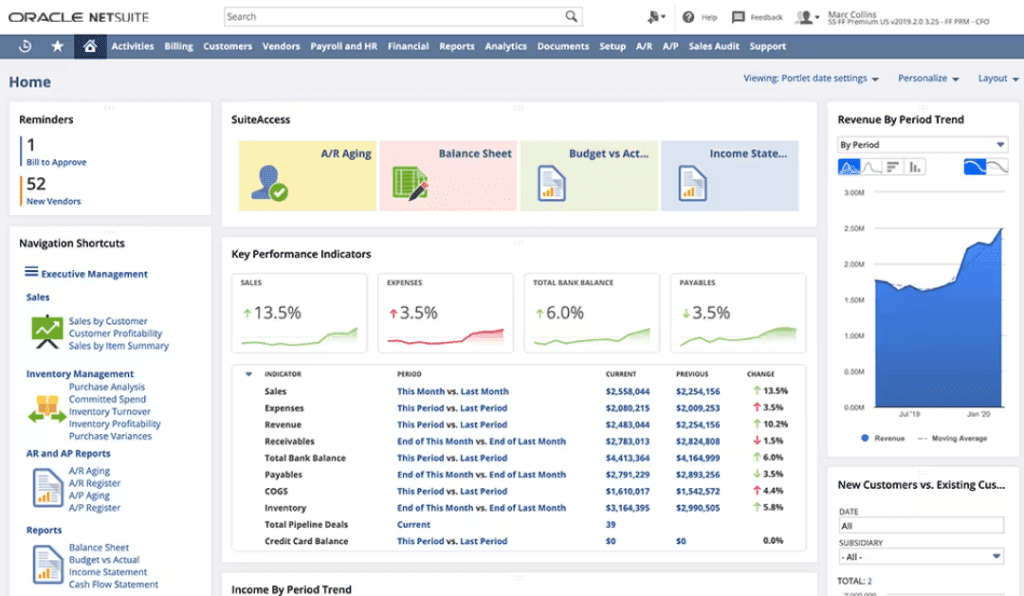

#3 Oracle NetSuite

Oracle NetSuite is a cloud-based ERP system designed to meet the specific needs of manufacturing enterprises. It offers a comprehensive platform for managing finance, supply chains, inventories, and manufacturing operations. Manufacturers can acquire detailed insights into their business performance using its powerful reporting and analytics solutions.

Oracle NetSuite also allows for cooperation with suppliers, partners, and customers via its integrated portal, which improves transparency and fosters stronger partnerships.

Oracle NetSuite, like SAP, can be fairly expensive, particularly for small and medium-sized businesses. The licensing, implementation, and customization expenses can quickly build up, making it less viable for smaller organizations with limited budgets. The system’s extensive capability and adaptability may sometimes be a disadvantage.

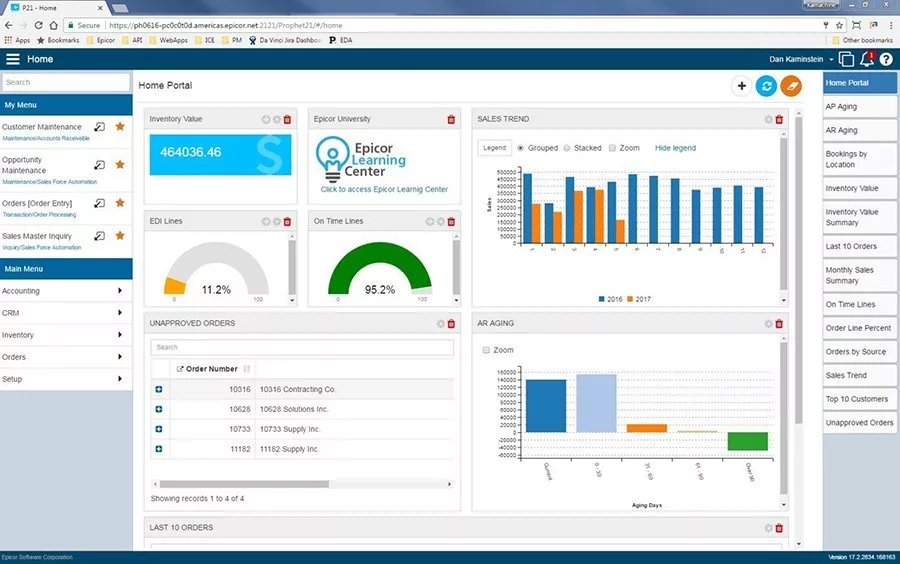

#4 Epicor

This solution is for any manufacturer with more than $1 million in revenue. Epicor provides production, supply chain, scheduling, and financial management. The platform enables manufacturers to use make-to-order, configure-to-order, and make-to-stock shop floor control while managing it all in the out-of-the-box software functionality.

However, it has limited flexibility in invoicing and order modifications, and there are no common integrations, but there is an open API on demand. It also features a very restricted import and export functionality, which is unusual given that Microsoft’s import/export capability is accessible in most of its mainstream products.

#5 Syspro

Syspro includes fundamental elements common to small ERP systems, such as shop floor control, inventory control, and finance services. It also offers robust scheduling capabilities, allowing it to use single- and multi-constraint scheduling. This enables the system to compare actual and estimated labor and manage resources for work-in-process. This is an important tool for smaller producers, as material costs can significantly impact earnings.

Despite its sophistication in fundamental manufacturing functionality, there are certain drawbacks linked to reporting and data management. Data from critical areas such as inventory and AR must be recorded at the same cost period to ensure accuracy. This restricts some data analysis and forces customers to remain watchful, whereas other companies manage the issue easily. Users have also complained about the confusing UI and the support team’s slow response times.

Identify the Influencing Factors To Find The Suitable ERP Solution for Your Manufacturing Business

Your company data reflects your fundamental business processes. While some of these processes are essential to your competitive advantage, others can limit your efficiency and overall progress.

At CMC Global, we start by identifying pain areas in your current processes in order to increase efficiencies and discover the best solution to support your long-term goals.

When deciding among the many ERP choices on the market, it is critical to analyze the features and benefits to find the best tool for your firm. While well-known companies such as SAP, Microsoft, and Sage may be familiar, you should also analyze each solution’s specific benefits and support.

Consulting with ERP specialists, like CMC Global, can help you choose the suitable ERP solution for your company.